Release by Exception - Should it be done?

- Binh Nguyen

- Dec 14, 2024

- 3 min read

What is release by exception? In manufacturing, there are instances where things may not always go as planned. It can be minor or major issue(s) in one or more areas and you have thousands and even millions of units awaiting final decision to release. When and/or how do you make exceptions to release these products?

These types of questions really relate to risk assessment. Per ICH Q9(R1) Quality Risk Management, risk is defined as the combination of the probability of occurrence of harm and the severity of that harm. In other words, if a product has the ability to harm a patient and it is likely to occur when a patient takes that product, you're releasing risk to the public.

What if my risks are minor, you may ask, can I release such a batch? This is a loaded question and it requires all hands-on deck type of answer. The reason is a risk may be minor in your assessment (i.e. a microbiologist shakes a product vial instead of vortexing it per SOP for an endotoxin testing) but may have a tremendous impact to harm the patient (i.e. endotoxin in product vial). The harm on this is the patient getting this product may get anaphylatic shock or even death when receiving a product vial with endotoxin yet it was released due to not following a "minor" step (i.e. vortex product vial) in a testing procedure. This is a true story where I was tasked to inspect a company where hundreds of adverse events relating to anaphylactic shock and deaths occurred as a result of using this product and the release of these batches was signed off because of negative endotoxin results. FDA own testing confirmed endotoxin in these products and the cause for negative endotoxin result was a simple step of not vortexing the product vial because endotoxin tends to stick to glass and did not come into solution when shaking by hands vs. vortexing. A what considers as a "minor" step in this endotoxin testing procedure was really a "major" step as the harm was "deadly."

If one were to look at risk further. This does not end at the endotoxin testing. Endotoxin in fact came from somewhere for it to get into the product. It was not just the laboratory error alone. In this reallife scenario, endotoxin was present in the company's water system. Yes the company was making its own WFI (water for injection). This relates to now material and facilities and equipment systems and also quality. When I conduct inspections, I often try to relate one issue found in one system to the next and really try to challenge the firm's quality systems and build a strong case to support violative actions.

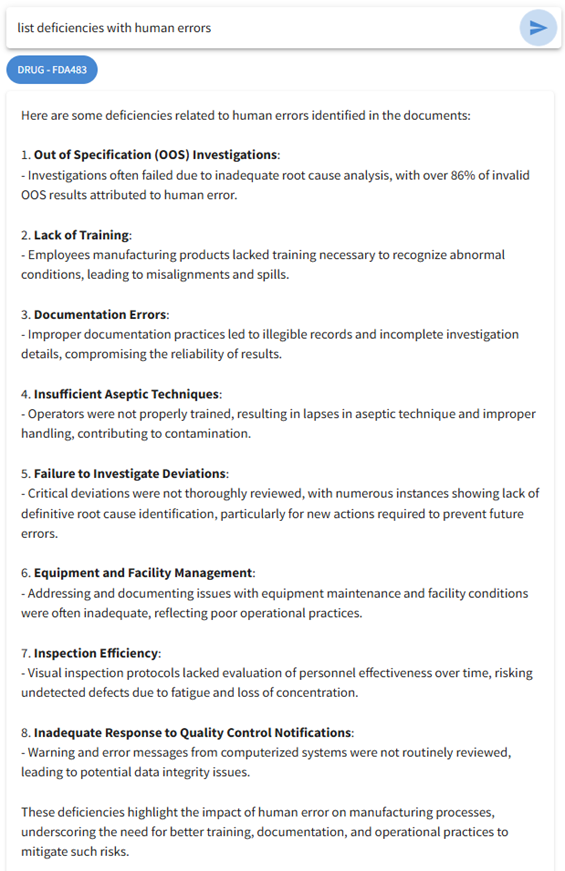

This is why I refer to above that this is an "all hands-on deck" type of assessment because once a deficiency is found in one area, it may relate to another area. The FDA issues the FDA-482 and FDA-483 to the most responsible person on site at the time of inspection. If there is harm to the public, highest level of management is often responsible and the consequences can be "jail" time besides other regulatory actions like warning letters, injunction, seizure, etc.

ICH Q9(R1) reiterates the importance of performing risk assessment covering the following operations which are essentially evaluating the 6 drug CGMP systems: Quality, Materials, Laboratory, Facilities and Equipment, Production, and Packaging and Labeling.

Examples for industry and regulatory operations (see Annex II):

• Quality management

• Development

• Facility, equipment, and utilities

• Materials management

• Production

• Laboratory control and stability testing

• Packaging and labeling

• Supply chain control

• Inspection and assessment activities

Below are some tools mentioned also in ICH Q9(R1) in Annex 1

• Basic risk management facilitation methods (flowcharts, check sheets etc.)

• Failure Mode Effects Analysis (FMEA)

• Failure Mode, Effects and Criticality Analysis (FMECA)

• Fault Tree Analysis (FTA)

• Hazard Analysis and Critical Control Points (HACCP)

• Hazard Operability Analysis (HAZOP)

• Preliminary Hazard Analysis (PHA)

• Risk ranking and filtering

• Supporting statistical tools

Is your company releasing products by exception? If so, I would consider assessing risks at multiple levels and systems to ensure the existing risk(s) if release not causing harm to the patients.

Comments