Artificial Intelligence (AI) Use in Government Applications and Inspection

- Binh Nguyen

- Jun 5, 2025

- 3 min read

Updated: Jun 5, 2025

On June 2nd, 2025, FDA Launches Agency-Wide AI Tool to Optimize Performance for the American People | FDA. Elsa is what it is called, a generative Artificial Intelligence (AI) tool designed to help employees from scientific reviewers to investigators work more efficiently by offering a platform for FDA employees to access internal documents while ensuring all information remains within the agency. The platform does not use data submitted by regulated industry. Elsa is to accelerate clinical protocol reviews, shorten the time needed for scientific evaluations, and identify high-priority inspection target.

What does this mean for the pharma industry? Be prepared for more sophisticated and equipped inspections from the Agency.

Per the 2025 State of Validation Report, here are top 3 ranked trends in validation related challenges:

So is your company audit ready? If you look at the top observations in 2024 vs. 2014, the bio/pharm industry still get pretty much similar citations with only 2 differences highlighted in # 6 & 7 yet # 11 & 12 moved up in ranking 10 years later from 2014 to 2024.

TOP 10 OBSERVATIONS IN 2024

211.22(d): QCU responsibilities and procedures not in writing/fully followed (201 times)

211.192: Failure to thoroughly review discrepancy, OOS (134 times)

211.100(a): Fail to establish adequate written production and process controls (126 times)

211.160(b): Lab controls not scientifically sound (119 times)

211.63: Equipment not appropriate design, size, suitably located (85 times)

211.67(a): Equipment and utensils not cleaned, maintained, sanitized (68 times)

211.113(b): Procedures to prevent microbiological contamination (69 times)

211.67(b): Written procedures not established/followed for equipment (60)

211.68(b): Inadequate computer control of master formula records (60 times)

211.166(a): Lack of written stability program (47 times)

TOP 12 OBSERVATIONS IN 2014

211.22(d): QCU responsibilities and procedures not in writing/fully followed (145 times)

211.160(b): Lab controls not scientifically sound (109 times)

211.192: Failure to thoroughly review discrepancy, OOS (94 times)

211.100(a): Fail to establish adequate written production and process controls (87 times)

211.67(b): Written procedures not established/followed for equipment (72 times)

211.113(b): Procedures to prevent microbiological contamination (72 times)

211.165(a): Testing and release for distribution (64 times)

211.67(a): Equipment and utensils not cleaned, maintained, sanitized (68 times)

211.68(a): Calibration/Inspection/Checking not done (54 times)

211.166(a): Lack of written stability program (47 times)

211.63: Equipment not appropriate design, size, suitably located (41 times)

211.68(b): Inadequate computer control of master formula records (23 times)

Why is our industry still facing the same challenges for decades? That's a billion question. If you look at the top 3 observations, they are from quality control unit, lab method, and inadequate investigations.

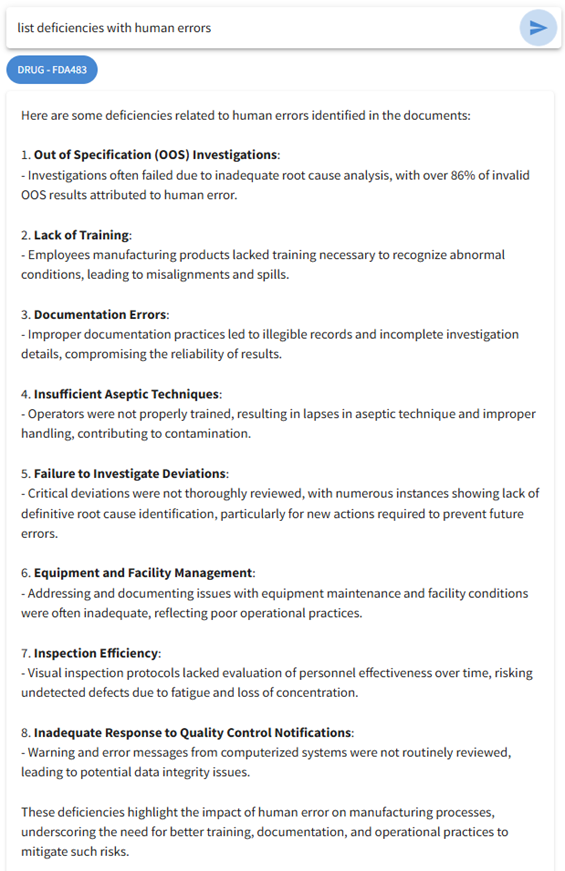

So what is the solution? At Wynngate Consulting, we provide proactive quality solutions to address the # 1 concern in the bio/pharma industry which is audit readiness. With ieQip (intelligent electronic Quality inspection platform) and our professional audit team, you already have a platform to act and think like regulators. With our AI empowered technology built in, you not only learn of prior mistakes from the industry through the FDA-483's and Warning Letters but much more scientific and regulatory literatures that have been filtered so you're not getting unknown sources from open source AI queries. For more information on the software, please email us at info@wynngateconsulting.com for a free demo. We also provide tailored quality training courses made specifically for your organizations specific auditing course to train your staff how to become FDA investigators. Ask us for more details on how we can bring such specialized regulatory compliance into your companies to be audit ready.

Comments